MANUFACTURING AND RESEARCH &DEVELOPMENT CAPABILITY

As one of the three major power equipment manufacturers in China, DTC possesses, domestically and even globally, the most advanced equipment manufacture base, being equipped with more than 2,600 sets of main machining equipment, including more than 400 sets of ”precise, large, rare” equipment. Numerical control rate of major products’ machining equipment exceeds 70%. Meanwhile, integrated application platforms taking SAP ERP system as the core and digital machining centers integrating the functions of “live transformation, visualization and intellectualization" are established. Numerical controls for machining large stationary parts, rotors, blades, small and medium-sized key parts have been realized comprehensively.

DTC’s research and test capability is at a leading position in China’s turbine industry. Engaging in the fundamental research, manufacturing process test and new product R&D, multi-level and full-range technical R&D platforms have been established. DTC is equipped with a 350t rotor high-speed dynamic balancer which is the largest in the world, a multi-stage turbine test rig, a gas turbine compressor test rig, a bearing test platform, an oil system test platform, creep endurance test machines and other advanced experimental equipment. Nuclear steam turbines’ welding rotor R&D and machining center, National Key Laboratory of Long-life High-Temperature Material, Turbine Core Technology Testing Laboratory, Heavy-duty Gas Turbine Testing Laboratory have been built up and put into use. Due to the features of the complexity of design and manufacturing process, and the high requirements of customization and operation service for turbine products, DTC keeps on pushing the integrated application of digitalized design and digitalized manufacture, by establishing the integrated design and manufacture platform of CAD/CAPP/CAM , the PLM (product lifecycle management system), OA, digitalized factory and other IT systems, which provides infinite impetus to DTC’s scientific and technological progress.

Rotor manufacturing equipment

CNC horizontal lathe

rotor fire-tree groove milling machine

350T HSB machine

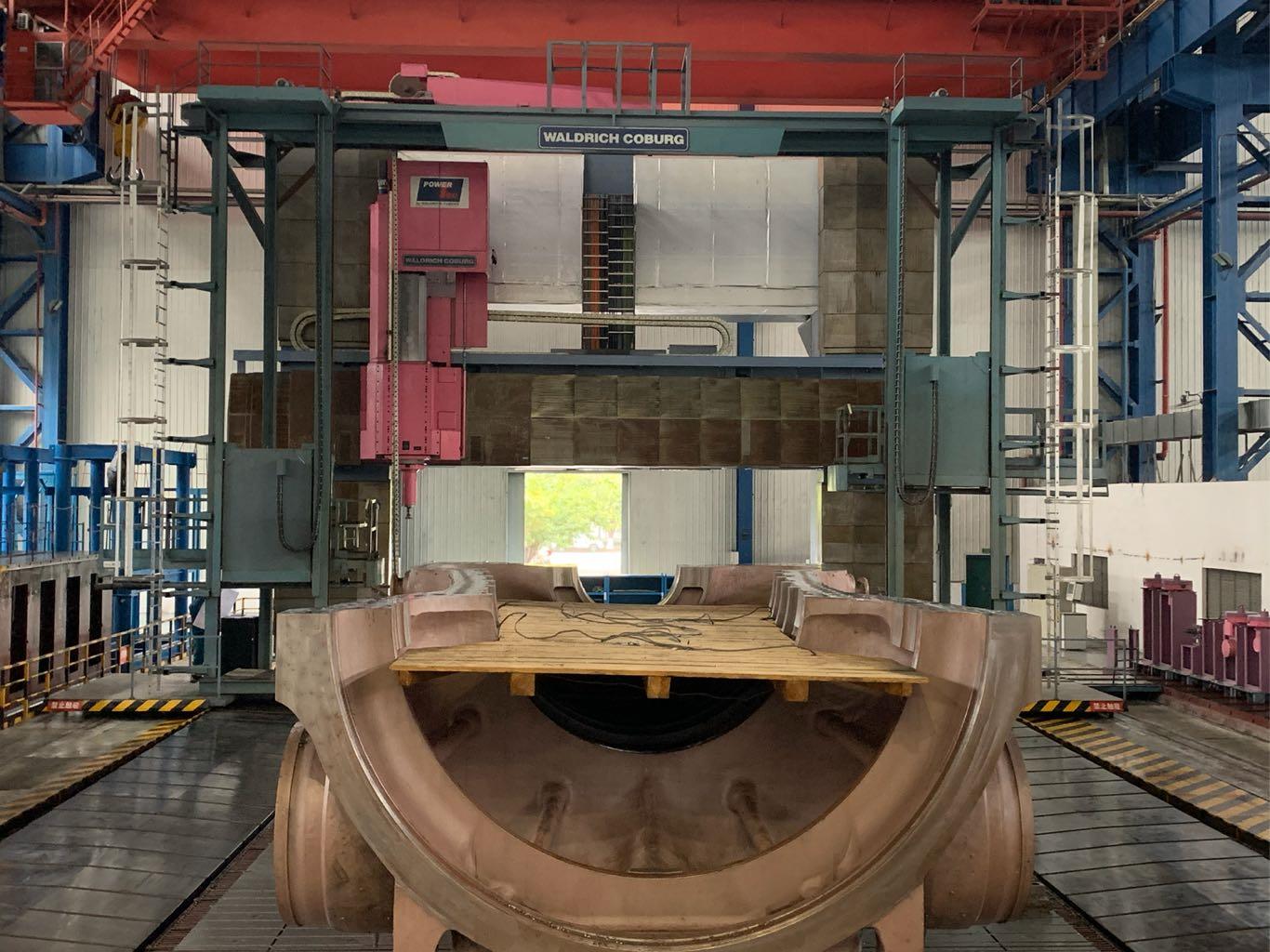

Static component manufacturing equipment

Large CNC gantry milling

Large CNC boring machine

Large CNC vertical lathe

Blade Manufacturing equipment

It has many other world-class high precision machining centers such as Switzerland、Germany and Italy,etc., including 141 sets of CNC equipment such as C.B.Ferrari 5-axis machining center、HAMUEL 5-axis machining center、DMG turning-milling machining center 、MAZAK turning-milling machining center ,etc.